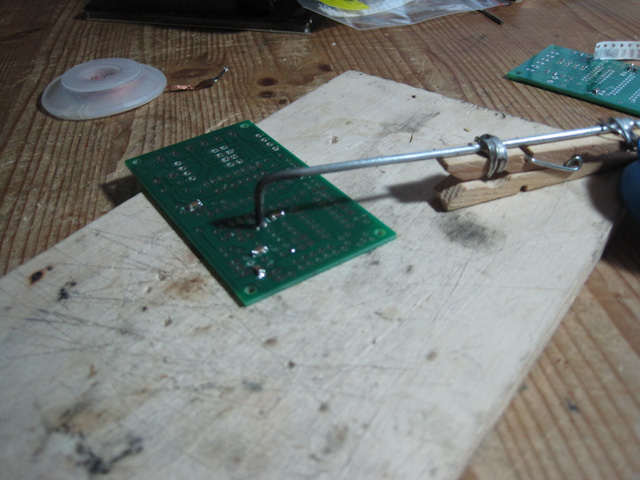

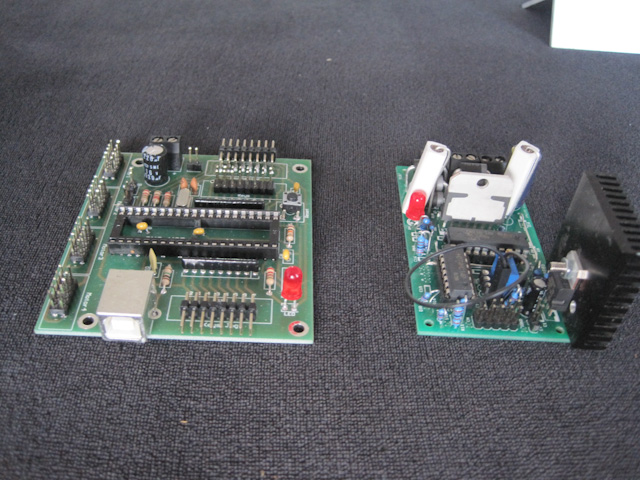

With quite some shame I admit that the reason you did not hear about this project for 8 months (!) is mainly because I was to lazy to drag myself to the next screw specialist. To put the parts together I had drilled in december I needed a special kind of screw with a flat head. They did not have those at my favorite hardware store and 6 weeks of holiday in Thailand distracted me, so it only came to my attention last week that a specialist is actually just around the corner…

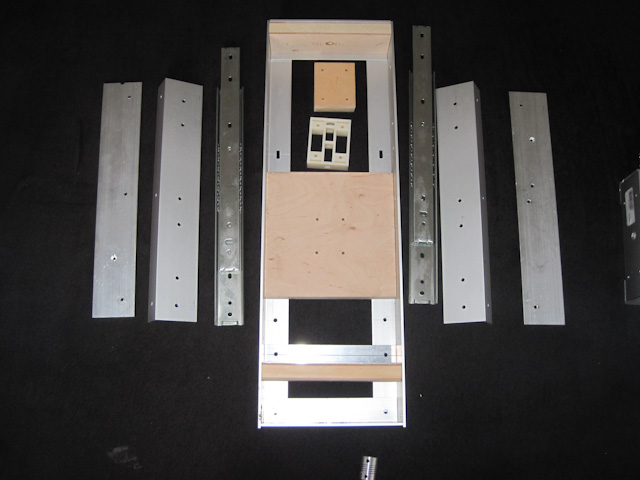

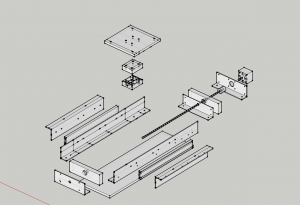

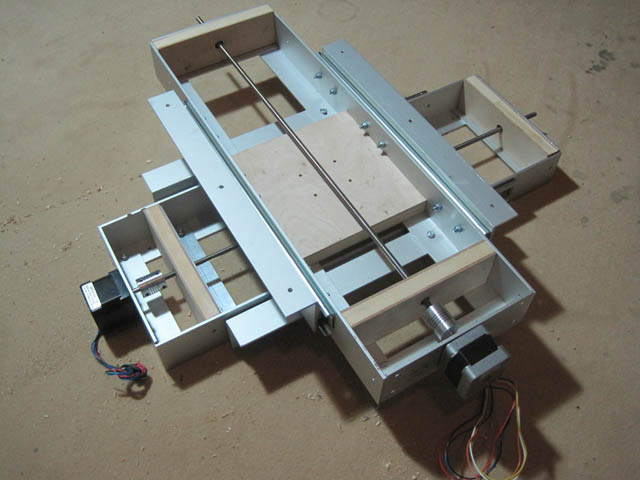

Anyway: here’s a first glimpse of the result. I can already see that it is full of design flaws. However, I will continue with it, knowing that I’ll learn a lot in the process. Main problem now will be to design a z-axis that fits around the thing. The table itself is about 60cm long, which means, I’ll need a base of at least 80×80 to fit the support for the last axis. Let’s see what I can do…

The actual table is not installed yet. It can move about 35 cm in each axis.