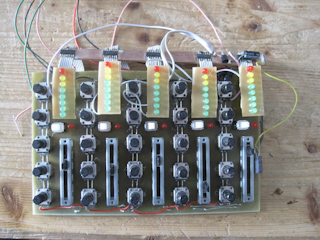

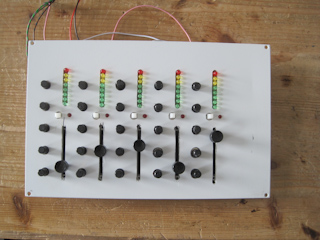

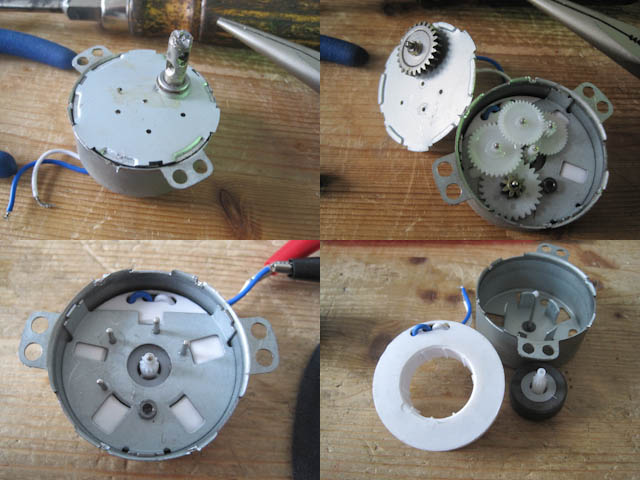

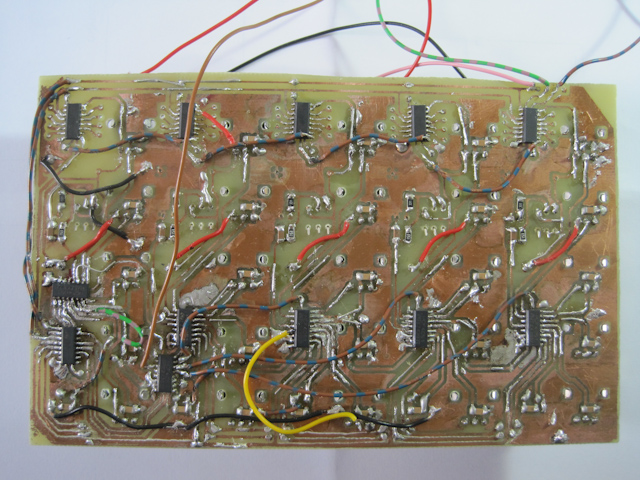

I’ve spent the past 2 years building machines and designing controller boards for them. These boards are all still in alpha status and I am quite sick of having to design the whole board anew whenever someone comes up with a new feature.

One could keep the whole thing extremely modular and design something around a master controller communicating with smaller boards that all have a certain purpose. But I want at least a certain functionality on one board to keep the wiring and communication programming as simple as possible. So currently I am thinking about building a stackable board that has the main processor and all the com I/Os on it that can be expanded by boards with extended features such as relays, decoupled outputs and such.

I was inspired by the [controllino]. I might as well buy one, but they seem to be in trouble with their part suppliers and I just can’t wait. Also, I want to do this by myself, learn stuff and make it available to everybody.

I did some research and stumbled over the [OpenPLC] project. I like what he did so far but I find the form factor a bit too clumsy for my purposes.

In the next weeks (and months, as these things tend to turn out) I will do some research/crowdsourcing as to different parts of the circuit and I will try to document it here. So whoever is up to such nerdy stuff: stay tuned :)