[UPDATE]

I finally made it happen!!!!

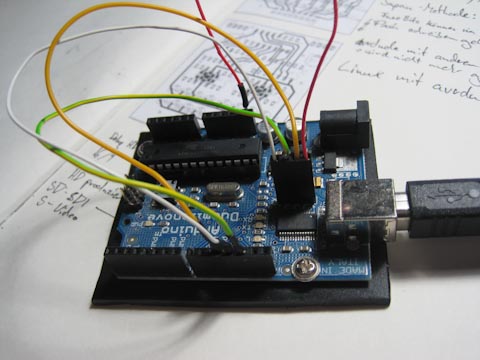

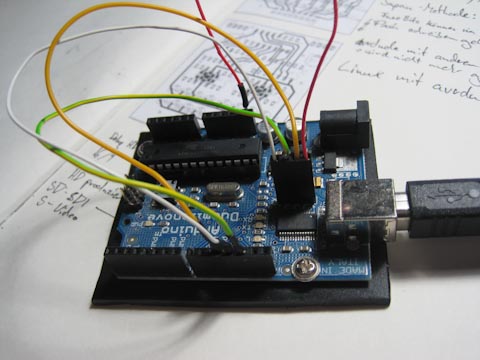

After two days of suffering I found a thorough explanation, how to burn the Arduino bootloader on an Atmega328. This is the solution.

The 'self programming' Arduino

[/UPDATE]

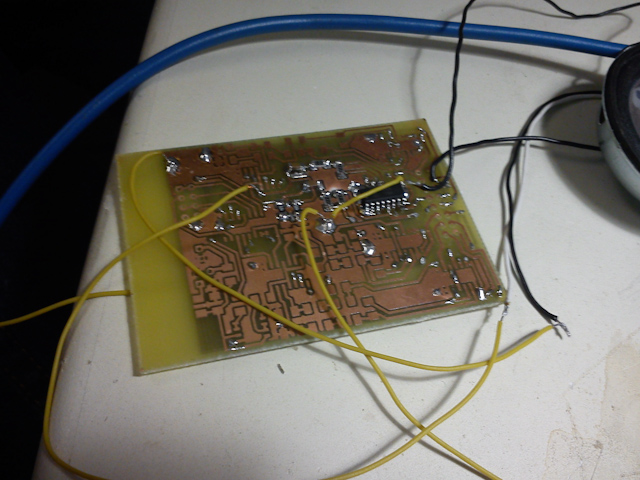

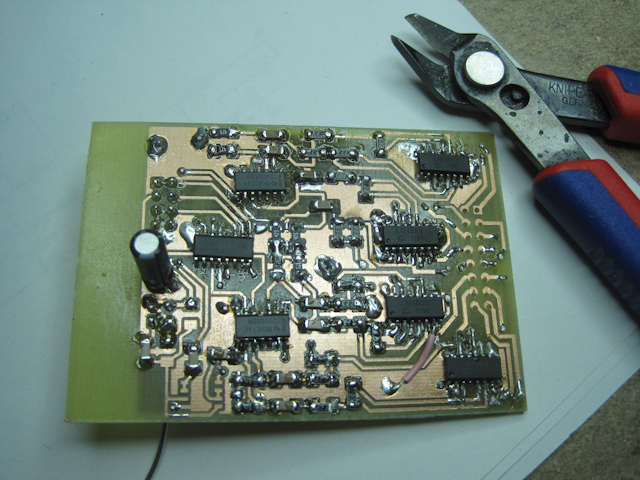

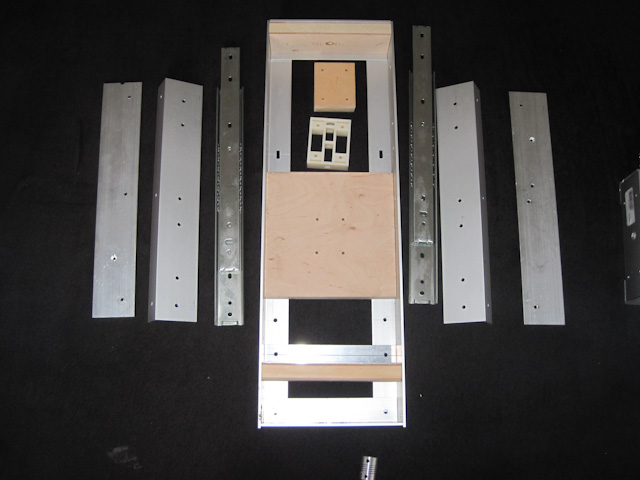

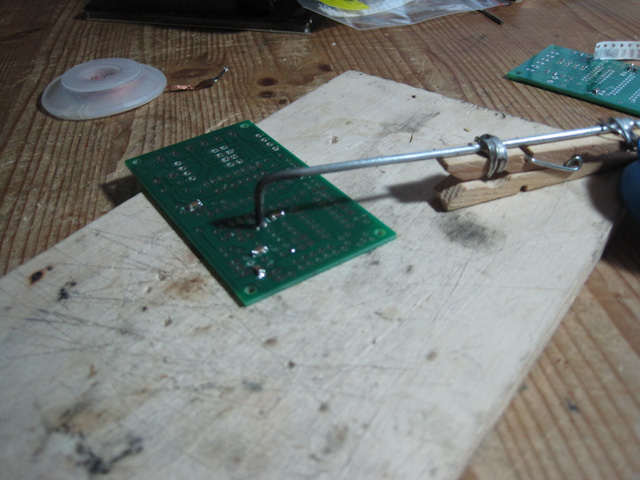

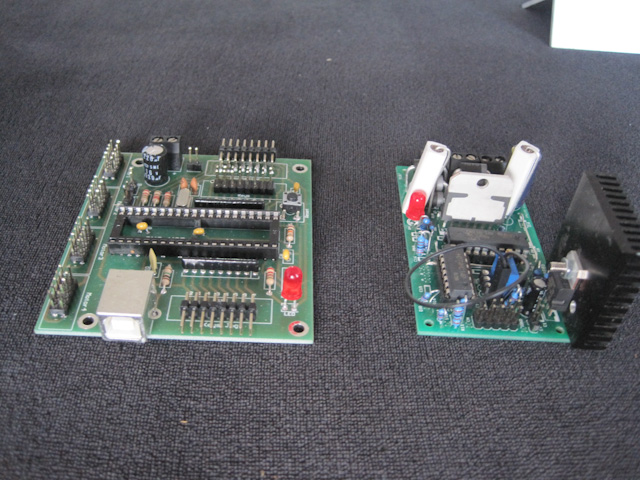

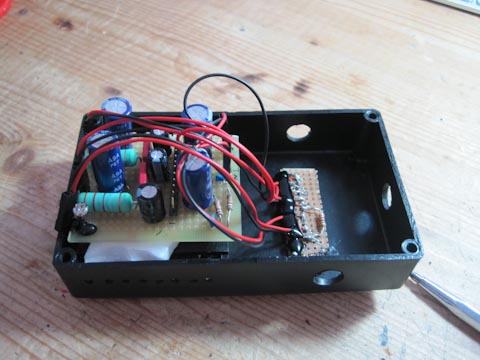

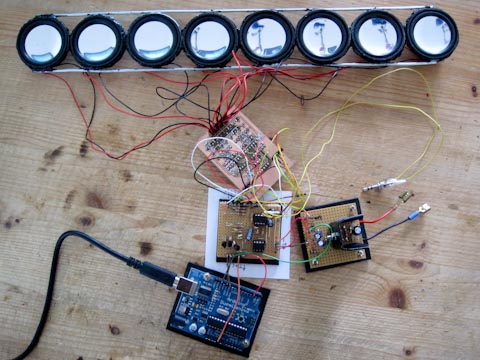

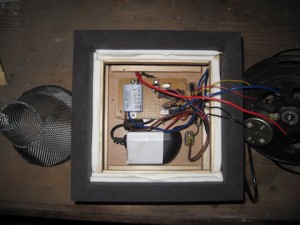

I wanted to start testing the freshly soldered boards for the Diskokugel when I had to discover, I had made a big mistake simply using the Atmega328 of my Arduino in my LED lamp. It turned out to be not quite as simple to replace since the Atmega needs a special bootloader to work in the Arduino board.

There are several ways to burn that bootloader into the chip. The easiest would be having an Arduino and programming it to do it. But since mine was without working chip, I had to look for other solutions. I found one that uses the FT232 on the board to program the Arduino itsself without an AVR writer. However, the solution programmed there is for Windows only. There apparently is a way to do it with a Mac but I wasted a whole day on trying to get it to work. It’s really tiring, installing package after package due to dependencies, having to compile it all, etc. I ended up compiling packages and, when I had finally done that, having forgot what other package I actually wanted to install in the first place.

I’ll try again tomorrow, taking the chip out of the lamp and putting it back into the Arduino. If the Arduino-as-AVRISP works, Ill simply burn me a stash of Arduinos…

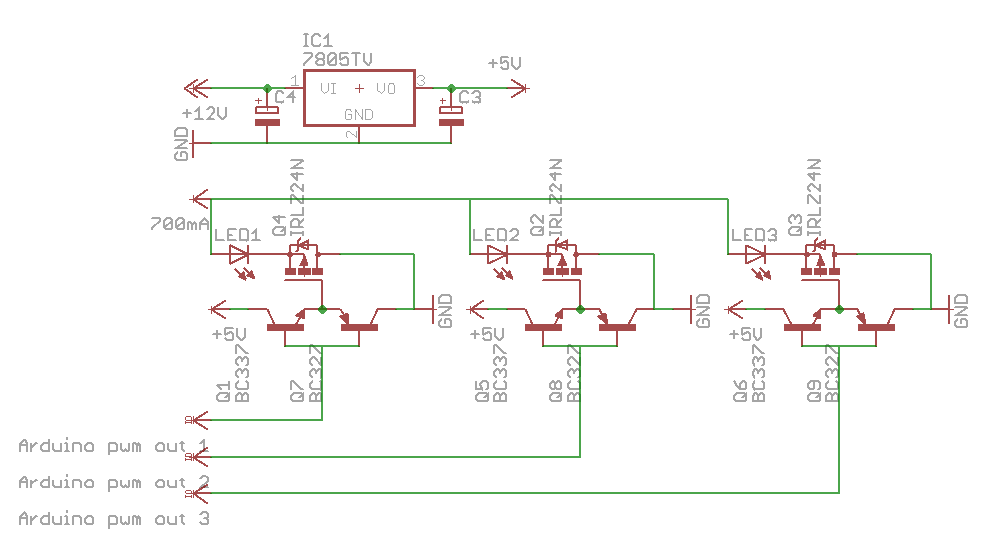

Of course, the Atmega32-8 is completely oversized for such a project, but it was at hand and programmable via the Arduino. I’m sure the extra constant current supply is also obsolete, but I didn’t get to try otherwise. Comments how to optimize the setup are always appreciated.

Of course, the Atmega32-8 is completely oversized for such a project, but it was at hand and programmable via the Arduino. I’m sure the extra constant current supply is also obsolete, but I didn’t get to try otherwise. Comments how to optimize the setup are always appreciated.