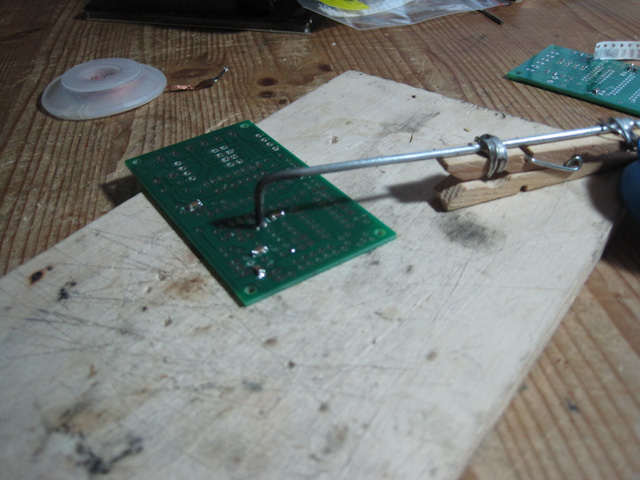

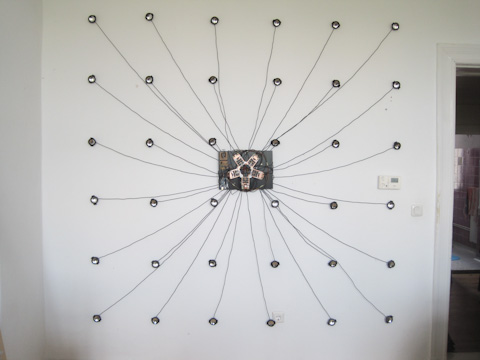

Coming closer to the point where the electronics for [Diskokugel] are settled, I start worrying about how to get sound and power into the turning thing. While with the sound I’ll most probably go for a wireless solution, with the power that’s highly unlikely. So I did an experiment with some ball bearings I had aquired for the (still pending) [cnc project]. I soldered wires to the in- and outside of the bearings to power a turning 1W LED. That resembled the setup I would have liked to use building a second [LED lamp]. Unfortunately even with a 1000µF capacitor on the LED end it wasn’t possible to keep the power straight. It might be helpfull to get the plastic caps of the bearings and apply a certain pressure on one side to keep the contact constant, but in general I abandoned the idea for high power connections. Considering the fact that the Diskokugel might use up to 200W at 5V there seems no way to keep the supply steady this way…

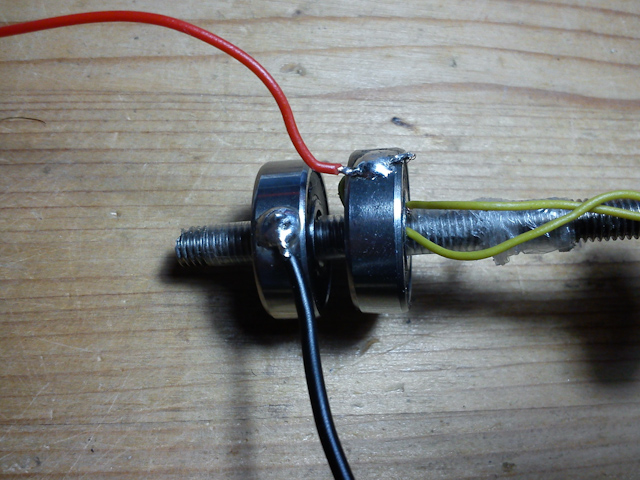

2 ball bearings on an axis as sliding contact